In a groundbreaking development, Scientists from the Energy and Catalysis Adventure Team (ECAT) have successfully developed a cost-effective, and environmentally friendly propylene catalyst for propylene production.This breakthrough, published as a cover story in the journal Science on July 19th CST time, boosts the development of sustainable catalysts for low-carbon olefin production technologies.

Propylene is one of the most produced chemicals globally and serves as a fundamental raw material in the manufacture of plastics, rubber, fibers, and pharmaceuticals. It holds significant strategic importance for the global petrochemical industry chains. In 2023, China's propylene production exceeded 60 million tons, accounting for approximately one-third of the global output, with a total value surpassing 600 billion yuan.

Among the various propylene production technologies, propane dehydrogenation (PDH) is preferred due to its high economic efficiency and reduced dependence on petroleum. However, traditional PDH catalysts rely heavily on expensive platinum or highly toxic chromium oxide, making the process costly and environmentally detrimental. The quest for a more efficient, cheaper, and greener next-generation propylene catalyst has thus become a global focal point in chemical research.

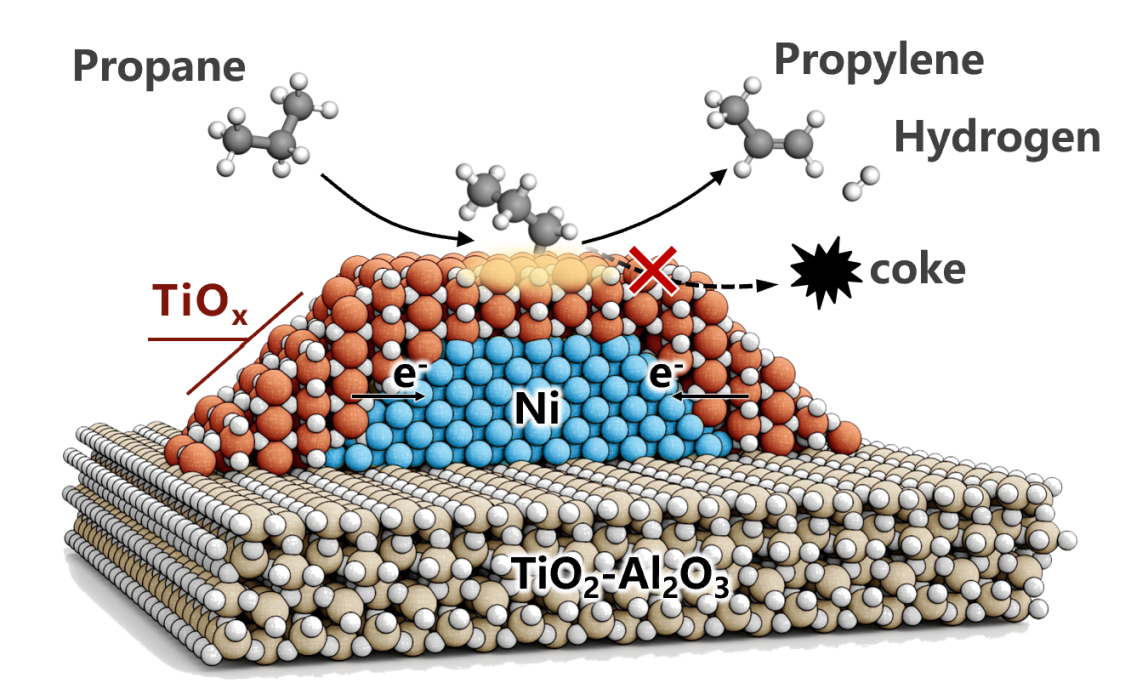

Defective TiOx overlayers catalyze propane dehydrogenation promoted by base metals

Addressing the current situation, the Energy and Catalysis Adventure Team (ECAT) at Tianjin University boldly proposed a scientific hypothesis that utilizes inexpensive and environmentally friendly oxides to interact electronically with metals, thereby enhancing the catalytic process. They developed a titanium oxide-nickel composite catalyst based on this hypothesis. Titanium is abundantly available on Earth, with China being one of the top resource-rich countries. Nickel is also plentiful globally.

The titanium oxide overlayers were tailored to achieve complete coating of an entire nickel nanoparticle through the strong metal-support interaction at elevated temperatures under H2 reduction, which remained intact under propane dehydrogenation reaction conditions. By doing so, the team achieved fine-tuned electronic transfer between titanium oxide and nickel, enhancing catalytic activity while suppressing side reactions such as cracking and carbon deposition.

This new catalyst demonstrates exceptional propylene selectivity and stability, outperforming international counterparts. It can reduce costs by 30-50% while ensuring non-toxic and low-energy consumption during catalyst preparation and use.

This innovation provides insights into the next generation of efficient, cost-effective, and sustainable propylene catalysts.

Paper link: https://www.science.org/doi/10.1126/science.adp7379

By Eva Yin